Everything you need know about TCOFF forged wheels

Before diving into the technical specifications and showcasing nerdy tech spec of our wheel designs, we want to share the core principles behind TCOFF Forged Wheels: affordability, reliability, and customizability.

Initially, we crafted wheels solely for internal use for custom spec for our shop cars, but the overwhelming interest from the community made us realize the widespread need for quality custom wheel solutions in the automotive world. After assisting numerous racing friends with their wheel specifications, we decided it was time to offer these options to the broader public, helping more racers and enthusiasts.

The reality is that most branded wheels on the market have limited specifications. For dedicated wheel companies, the focus on quantity and sales volume is crucial for profitability. This often means they are unwilling to stock special-spec wheels or provide custom specifications unless you're a major sponsored entity or exceptionally wealthy.

However, this isn't usually the case at the grassroots and enthusiast community levels. Whether it's a garage builder, a shop built car, or a team, there are often unique needs such as a specific offset, wider track spindles, or fender flares. We've experienced these challenges firsthand, especially when setting up wheels for our wide-bodied, time attack cars. We are not the type to simply stack spacers and consider it done. we didnt even mentioned about the annoyoing hub-centric rings. If you've ever spent hours searching for the right wheel setup, you know exactly what we're talking about.

This is why we invested heavily in a production line at the world level manufacture Dicastal factory, stepping up our game in racing forged wheel. We are appreciate for the support from our racing friends and the trust our customers,have placed in our products, making this venture possible.

So, What's special about TCOFF Motorsports(TCM) Forged racing wheels?

Affordable

We hate to say it, but let’s face it: wheels are consumable items, especially for hardcore track enthusiasts and wheel-to-wheel racers. Therefore, affordability is a crucial consideration when purchasing wheels. Unlike other "big brands" that outsource everything and add a significant markup, we maintain our own production line in the factory. This setup eliminates the need for outsourcing and middlemen, reducing costs. Our factory handles everything from forging to machining and the final finish. This not only reduces lead times and ensures quality control but also significantly cuts costs

In-house Customizble Design

Yes, we have our own CAD designers and engineers, who are also in the field of racing and track enthusiasts themselves. This means they know exactly what the wheels need for optimal performance and balancing aesthetics, rigidity, and manufacturing costs.

What’s more, our wheels are fully customizable! You can specify custom sizes, offsets, bore centers, bolt patterns, and finishes. Even If you’re looking for a unique design and are willing to invest a little more time with our designers, our team can make it happen for you.

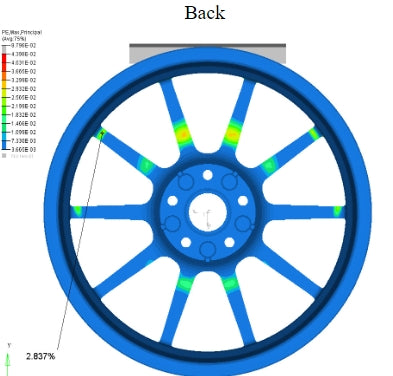

Every time a wheel's offset or size is altered, the structure changes, necessitating rigorous testing to ensure durability. Every custom spec wheel undergoes FEA (Finite Element Analysis) to simulate real-world forces. We then produce an additional test sample to evaluate in real-world conditions before proceeding with full production—and don't worry, the cost of the test sample is on us.

Reliable

Wheels are consumables; but they also need to withstand various unexpected events on the roads and race tracks. We prioritize usability and cost-effectiveness during the design process. Our goal isn’t to achieve extreme lightness—a common marketing gimmick—but to design wheels that first and foremost offer maximum rigidity while still optimizing weight reduction. This ensures they can withstand reasonable impacts from curbs and occasional light bumps from other race cars as you fighting for racing line on the track.

If bad thing happends, we also offer individual replacements for custom wheels.

More Technical Information

10K Tons Forging Pressure

Forged wheels are made from a solid piece of aircraft grade Aluminum Cylinder that is heated and pressed under immense pressure to form the wheel’s shape (Forged Blank). This process aligns the grain structure of the metal, making the wheel much stronger than those made by casting.

Made by Motorsports Blank

ALL TCOFF Forged wheel use exactly same dedicated motorsports grade forged blanks that forged in our factory. Own supplied blank provide much more flexibility of brake clearance, spoke design and size and width.

100% Customizable

Thanks to our in-house designer and engineerers, we can customize wheels to your specific size and offset specs.

Every custom setup will go through FEA analysis and physically test to meet all JWL/ VIA/ TUV/ DOT Standards

TCOFF FORGED WHEEL FEATURES

-

Knurled Bead Seat

All TCOFF Forged wheels are equipped with a gear-cut knurled bead seat, enhancing the grip between the tire and the rim. This design feature prevents tire creep and slippage, thereby improving traction during high-performance driving conditions

-

Barrel Reinforcement Ribs

Wider barrel means more distance between rim flanges, which means more leverage force under heavy or shocking loads, our reforcement ribs can be a extra safety.

-

Big Brake Clearance

Our in-house monoblock blank provide maxinium big brake clearance. you may fit up to 390mm at the front with 18inch TC-XR (*based on caliper design, check with your caliper manufacture for the size)